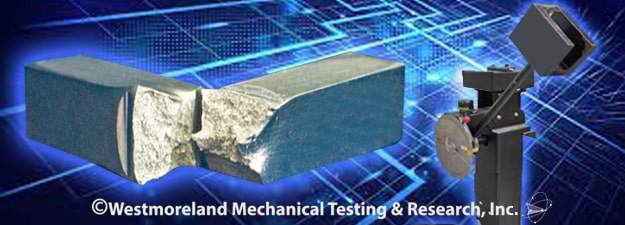

The usual test sequence is as follows: After the preparation and temperature conditioning of the specimen, the initial drop-weight test is conducted at a test temperature estimated to be near the NDT temperature. Depending upon the results of the first test, tests of the other specimens are conducted at suitable temperature intervals to establish the limits within 10°F (5°C) for break and no-break performance. A duplicate test at the lowest no-break temperature of the series is conducted to confirm no-break performance at this temperature.

In 1984, the method of applying the crack-starter weld bead was changed from a two-pass technique to the current single-pass procedure, and the practice of repair-welding of the crack-starter weld bead was prohibited. For steels whose properties are influenced by tempering or are susceptible to temper embrittlement, the nil-ductility transition (NDT) temperature obtained using the single-pass crack-starter weld bead may not agree with that obtained using the previous two-pass crack-starter weld bead, or when the crack-starter bead was repaired.

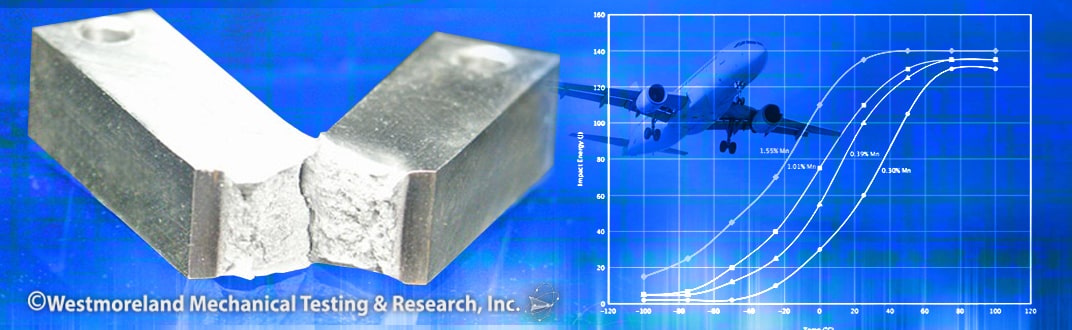

The fracture-strength transitions of ferritic steels used in the notched condition are markedly affected by temperature. For a given "low" temperature, the size and acuity of the flaw (notch) determines the stress level required for initiation of brittle fracture. The significance of this test method is related to establishing that temperature, defined herein as the NDT temperature, at which the "small flaw" initiation curve falls to nominal yield strength stress levels with decreasing temperature.

Interpretations to other conditions required for fracture initiation may be made by the use of the generalized flaw-size, stress-temperature. The diagram was derived from a wide variety of tests, both fracture-initiation and fracture-arrest tests, as correlated with the NDT temperature established by the drop-weight test. Validation of the NDT concept has been documented by correlations with numerous service failures encountered in ship, pressure vessel, machinery component, forged, and cast steel applications. For complete information on ASTM E208, go to www.astm.org