Custom Analyzation

Custom Analyzation

WMT&R designs and writes proprietary software to analyze test results.

"With over five decades of materials testing experience, and key Nadcap and A2LA accreditations, WMT&R is uniquely qualified to test materials created using additive manufacturing processes. "

Expedited Additive Manufacturing Testing Services Are Available- Contact Us Today!

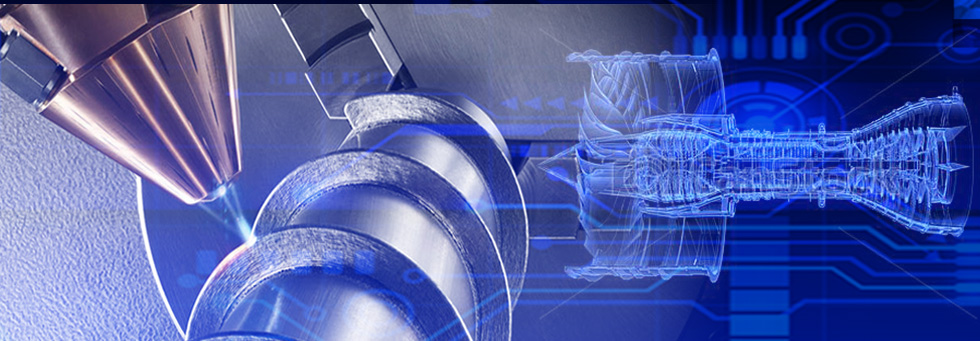

Westmoreland Mechanical Testing and Research, Inc (WMT&R) is a trusted testing partner for the aerospace primes and other companies in advanced industries such as automotive, medical, and power generation who are leading the adoption of additive manufacturing materials and processes.

In addition, WMT&R has been working closely with the leaders of additive manufacturing to learn more about the characteristics of these materials and advance the additive manufacturing processes.

Westmoreland Mechanical Testing & Research, Inc (WMT&R) provides comprehensive comparison testing and research services for Additive Manufacturing and 3D printed materials including axial fatiguing, tensile, compression, shear and flexural tests and many more

WMT&R provides the following additive manufacturing material testing services:

Direct Metal Laser Melting, Direct Metal Laser Sintering, Selective Laser Melting, and Selective Laser Sintering are all very nearly the same process, with the main difference being applicable materials and the temperatures required to fuse the material together. Selective Laser Sintering and Selective Laser Melting can refer to any material. Direct Metal Laser Sintering and Direct Metal Laser Melting refer only to metals They are commonly done using a Yb-YAG laser and require an inert gas environment such as Argon. Electron Beam Melting uses an electron beam instead of a laser to melt the metal that is being built. EBM can be used on both powdered metals and metal wire. In the case of metal wire, the feed wire is melted and welded in successive layers on a substrate.

With over five decades of materials testing experience and key Nadcap and A2LA accreditations, Westmoreland Mechanical Testing & Research, Inc (WMT&R) is uniquely qualified to test materials created using additive manufacturing processes.

WMT&R's services are providing hundreds of companies with a unique competitive advantage. We are materials testing specialists in additive manufacturing on many different types of specimens, including extensive specimen traceability services. WMT&R can provide materials testing on additive manufacturing materials such as solids, metals, powders, and as-built specimens.

Custom Analyzation

Custom Analyzation

WMT&R designs and writes proprietary software to analyze test results.

Superior Turnaround Time

Superior Turnaround Time

To ensure the best turnaround time on your projects, WMT&R designs and machines specialized fixtures on-site. Expedited services are available, ask us how.

Customizable Test Setups and Extensive Scope

Customizable Test Setups and Extensive Scope

For your unique testing needs WMT&R has the resources, experience, and testing capacity to answer all of your materials questions for any application, customizable to your requirements.

Test Variety of Sample Sizes

Test Variety of Sample Sizes

WMT&R has the flexibility and resources to accommodate a broad range of sample sizes with our machine capacity ranging from 10 grams to 1,000,000 lbs.

Varying Temperature Ranges

Varying Temperature Ranges

WMT&R has a variety of customizable test setups and equipment for testing specimens in a number of environments and temperatures, from Cryogenic to 3000°F, high humidity to fluid immersion, we can help you mimic any real world application or requirement.

On-Site Machine Shop

On-Site Machine Shop

The testing laboratories at WMT&R are supported by an on-site machine shop, available 24 hours a day, seven days a week to manufacture test specimens to meet any customer schedule.