Tension tests provide information on the strength and ductility of materials under uniaxial tensile stresses. This information may be useful in comparisons of materials, alloy development, quality control, and design under certain circumstances. The results of tension tests of specimens machined to standardized dimensions from selected portions of a part or material may not totally represent the strength and ductility properties of the entire end product or its in-service behavior in different environments.

These test methods are considered satisfactory for acceptance testing of commercial shipments. The test methods have been used extensively in the trade for this purpose. For complete information on ASTM E8, go to astm.org.Tensile Testing

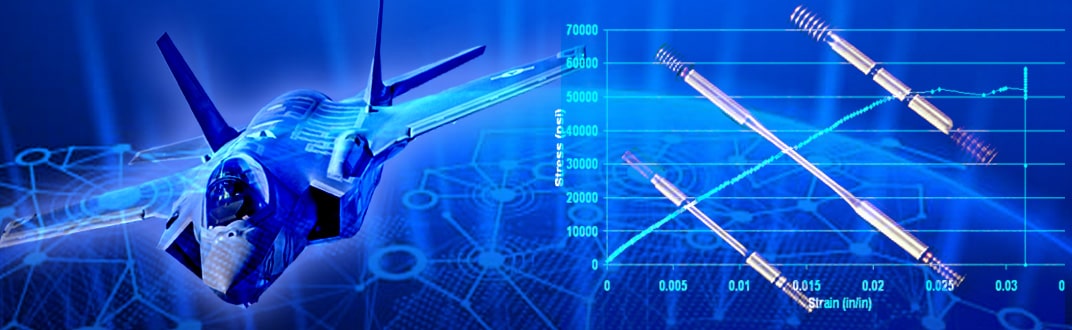

The Tensile Testing Laboratory at Westmoreland Mechanical Testing & Research, Inc (WMT&R) provides tensile testing what is ideal for analyzing a materialĺs strength against maximum stress from being stretched or pulled before breaking. Tensile testing is an important materials test to select a specific material for an application, for quality control, and to predict how a material will react to varying forces.ö

Expedited Tensile Testing Services Are Available- Contact Us Today at 724-537-3131

- Customized Test Setups

- Extensive Scope (Unique to Customer Specifications, International and Industry Standards)

- Sample Size Capacity Range from 25 grams to 1,000,000 lbs.

- Capability to Test Variety of Tensile and Specimen Types

- On-Site Machine Shop and Specimen Preparation

- Ability to Test Metals, Alloys, Composites, Polymers, Ceramics, Plastics, Wood and More

- Temperature Ranges from Cryogenic to 2200ºF

- Extensive Number of Machines and Fixtures

- NADCAP and ISO 17025 Accredited

- Determine Ultimate Tensile Strength, Yield Strength, True Stress and Strain, Engineering Stress and Strain, Elastic Modulus, Fracture Stress, Modulus of Toughness, and Modulus of Resilience

What Is Tensile Testing?

An axial pull when exerted upon the material in accordance with agreed upon standards, and the results measured with scientifically accurate methods.

Tensile Testing is one of the most widely used mechanical tests completed on materials. By measuring the force required to elongate a specimen to breaking point, material properties can be determined that will allow design engineers to predict how materials and products will behave in their intended applications.

The quality of materials used in manufacturing play a crucial role in the development of products. The Tensile Testing lab at WMT&R has helped thousands of companies from around the world determine the behavior of a material with their Tensile Testing capabilities.

Why Perform a Tensile Test?

Many properties of a material may be determined by use of tensile testing. Tensile testing provides data on strength and ductility of metals under uniaxial tensile forces. The tensile strength of a metal is essentiality its ability to withstand tensile loads without failure. This is an important factor in metal forming process since brittle metals are more likely to rupture. A tensile test is commonly used to select a material for an application, for quality control, and to predict how a material will react under different types of forces. WMT&R provides several types of tensile testing performed under standardized or customized specifications. Tensile Tests can be performed at room temperature, elevated temperatures (-452 to 2200°F), with a variety of specimen types, fixtures and customizable test setups.

Tensile Testing Services

Some of the tensile test procedures we can perform are:

- Root, Face, and Side Bend Testing

- Proof Loading of Testing Materials

- Breaking Load Testing of Full Size Bolts and Studs

- Tensile for Room and Non-Ambient Temperature Testing

- Slow Strain Rate Testing

- Tubing Testing

- Compression Strength Testing (Composites)

- Impact Testing (IZOD, CTOD)

- Double Shear Testing

- Single Shear Testing

- Shear Testing on Flat Specimens

- Double Shear on Rods, Wires, Rivets in Tension

Customizable Tensile Testing Capabilities

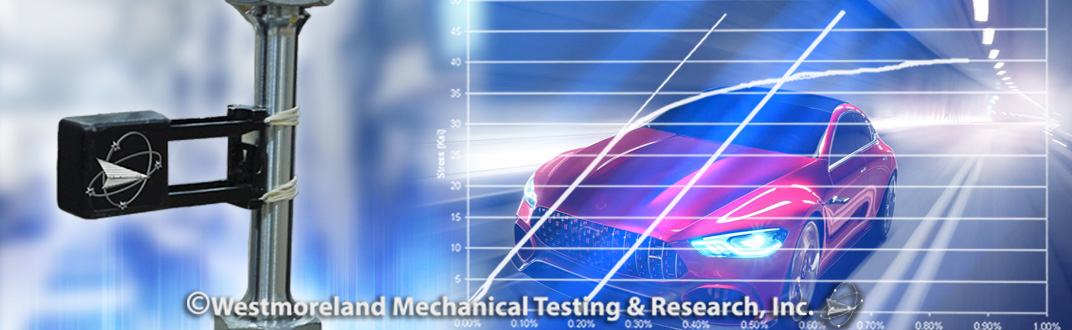

The Tensile Testing laboratory at WMT&R can provide standardized and customizable tests for a variety of industry applications and materials including metals, alloys, composites, polymers, ceramics, plastics, wood and more.

Our tests can determine important properties of your material determined by tensile tests, including:

Ultimate Tensile Strength is determined by dividing the highest load experienced by the specimen before rupture by the original cross section of the test specimen. Yield Strength is determined by the amount of stress that is required to begin plastic deformation of the test specimen.

The Elastic Modulus or Young's Modulus is determined by the ratio of stress to strain below the elastic limit. The Modulus of Elasticity measures the stiffness of a material but it only applies to the portion of the test where the ratio of stress to strain is constant. On an x/y axis graph of the Tensile Test this portion of the test would be represented by the straight line portion of the graph prior to the beginning of the curve. At this point in the test, if the load were to be removed, the test specimen would return to its original condition. After this point in the test, plastic deformation begins to occur, and the test specimen will not return to its original proportions upon relaxation of the load.

The Offset Method for determining Yield Strength is used when the material being tested does not show an easily identifiable departure point from the linear elastic region on the graph. Many metals and most plastics fall into this category. An offset is specified as a % of strain. A line is drawn from the offset with the same slope as the Modulus of Elasticity. The stress value at the intersection of the offset line with the line of the linear elastic region is then used for the Yield Strength by Offset Method.

Modulus of Toughness is determined in the Tensile Test by calculating the total area under the stress/strain curve to the point of failure.

Modulus of Resilience is the energy that can be absorbed per unit volume without causing permanent distortion. And may be calculated by integrating the stress/strain curve from zero to the elastic limit and then dividing by the original volume.

Fracture Stress is the load at fracture divided by the cross sectional area at fracture.

Engineering Stress and Strain is the ratio of the applied load to the undeformed cross-sectional area, while, True Stress and Strain is the ratio of the applied force to the instantaneous cross-sectional area. True Stress and Strain calculates for the reduced area of the test specimen as plastic deformation occurs. For most applications involving small strain rates (less than 5%) Engineering Stress and Strain are accurate enough. For larger strain rates, the more involved calculations to arrive at True Stress and Strain become necessary.

Standardized Tensile Testing Services

We can provide customizable and standardized testing specific to your specification and requirements. Some of the standardized tensile testing we perform include:

ASTM E8

Standard Test Methods for Tension Testing of Metallic Materials

These test methods cover the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of yield strength, yield point elongation, tensile strength, elongation, and reduction of area.

ASTM E21

Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials

These test methods cover procedure and equipment for the determination of tensile strength, yield strength, elongation, and reduction of area of metallic materials at elevated temperatures.

Determination of modulus of elasticity and proportional limit are not included.

Tension tests under conditions of rapid heating or rapid strain rates are not included. The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. The elevated-temperature tension test gives a useful estimate of the ability of metals to withstand the application of applied tensile forces. Using established and conventional relationships it can be used to give some indication of probable behavior under other simple states of stress, such as compression, shear, etc. The ductility values give a comparative measure of the capacity of different materials to deform locally without cracking and thus to accommodate a local stress concentration or overstress; however, quantitative relationships between tensile ductility and the effect of stress concentrations at elevated temperature are not universally valid. A similar comparative relationship exists between tensile ductility and strain-controlled, low-cycle fatigue life under simple states of stress. The results of these tension tests can be considered as only a questionable comparative measure of the strength and ductility for service times of many hours. Therefore, the principal usefulness of the elevated-temperature tension test is to assure that the tested material is similar to reference material when other measures such as chemical composition and microstructure also show the two materials are similar. For complete information on ASTM E8, go to astm.org

Mil-STD-1312-18

Superseded by NASM1312-18, Standard Practice, National Aerospace Standard, Fastener Test Methods; Method 18, Elevated Temperature Tensile Strength

Mil-STD-1312-8

Superseded by, NASM1312-8, Standard Practice, National Aerospace Standard, Fastener Test Methods, Method 8, Tensile Strength

ASTM A370

Standard Test Methods and Definitions for Mechanical Testing of Steel Products, Sections 5-13 Tension

These test methods cover procedures and definitions for the mechanical testing of steels, stainless steels, and related alloys. The various mechanical tests herein described are used to determine properties required in the product specifications. Variations in testing methods are to be avoided, and standard methods of testing are to be followed to obtain reproducible and comparable results. In those cases in which the testing requirements for certain products are unique or at variance with these general procedures, the product specification testing requirements shall control.

The primary use of these test methods is testing to determine the specified mechanical properties of steel, stainless steel and related alloy products for the evaluation of conformance of such products to a material specification under the jurisdiction of ASTM Committeeáand its subcommittees as designated by a purchaser in a purchase order or contract.

These test methods may be and are used by other ASTM Committees and other standards writing bodies for the purpose of conformance testing. The material condition at the time of testing, sampling frequency, specimen location and orientation, reporting requirements, and other test parameters are contained in the pertinent material specification or in a General Requirement Specification for the particular product form. Some material specifications require the use of additional test methods not described herein; in such cases, the required test method is described in that material specification or by reference to another appropriate test method standard. These test methods are also suitable to be used for testing of steel, stainless steel and related alloy materials for other purposes, such as incoming material acceptance testing by the purchaser or evaluation of components after service exposure. As with any mechanical testing, deviations from either specification limits or expected as-manufactured properties can occur for valid reasons besides deficiency of the original as-fabricated product. These reasons include, but are not limited to: subsequent service degradation from environmental exposure (for example, temperature, corrosion); static or cyclic service stress effects, mechanically-induced damage, material inhomogeneity, anisotropic structure, natural aging of select alloys, further processing not included in the specification, sampling limitations, and measuring equipment calibration uncertainty. There is statistical variation in all aspects of mechanical testing and variations in test results from prior tests are expected. An understanding of possible reasons for deviation from specified or expected test values should be applied in interpretation of test results. For complete information on ASTM A370, go to astm.org

ASTM D638

Standard Test Method for Tensile Properties of Plastics

This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed.

This test method is applicable for testing materials of any thickness up to 14 mm (0.55 in.). However, for testing specimens in the form of thin sheeting, including film less than 1.0 mm (0.04 in.) in thickness, ASTM standardáD882áis the preferred test method. Materials with a thickness greater than 14 mm (0.55 in.) shall be reduced by machining. This test method includes the option of determining Poisson's ratio at room temperature.

This test method is designed to produce tensile property data for the control and specification of plastic materials. These data are also useful for qualitative characterization and for research and development. Some material specifications that require the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Tensile properties are known to vary with specimen preparation and with speed and environment of testing. Consequently, where precise comparative results are desired, these factors must be carefully controlled. It is realized that a material cannot be tested without also testing the method of preparation of that material. Hence, when comparative tests of materials per se are desired, exercise great care to ensure that all samples are prepared in exactly the same way, unless the test is to include the effects of sample preparation. Similarly, for referee purposes or comparisons within any given series of specimens, care shall be taken to secure the maximum degree of uniformity in details of preparation, treatment, and handling. Tensile properties provide useful data for plastics engineering design purposes. However, because of the high degree of sensitivity exhibited by many plastics to rate of straining and environmental conditions, data obtained by this test method cannot be considered valid for applications involving load-time scales or environments widely different from those of this test method. In cases of such dissimilarity, no reliable estimation of the limit of usefulness can be made for most plastics. This sensitivity to rate of straining and environment necessitates testing over a broad load-time scale (including impact and creep) and range of environmental conditions if tensile properties are to suffice for engineering design purposes. For complete information on ASTM D638, go to astm.org

ASTM F606 / F606 M

Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets

These test methods cover establishment of procedures for conducting tests to determine the mechanical properties of externally and internally threaded fasteners, washers, direct tension indicators, and rivets.

Property requirements and the applicable tests for their determination are specified in individual product standards. In those instances where the testing requirements are unique or at variance with these standard procedures, the product standard shall specify the controlling testing requirements. For complete information on ASTM F606 / F606M, go to astm.org

ASTM D3039 / D3039M

Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials

This test method determines the in-plane tensile properties of polymer matrix composite materials reinforced by high-modulus fibers. The composite material forms are limited to continuous fiber or discontinuous fiber-reinforced composites in which the laminate is balanced and symmetric with respect to the test direction.

The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard. A thin flat strip of material having a constant rectangular cross section is mounted in the grips of a mechanical testing machine and monotonically loaded in tension while recording the force. The ultimate strength of the material can be determined from the maximum force carried before failure. If the coupon strain is monitored with strain or displacement transducers then the stress-strain response of the material can be determined, from which the ultimate tensile strain, tensile modulus of elasticity, Poisson's ratio, and transition strain can be derived.

This test method is designed to produce tensile property data for material specifications, research and development, quality assurance, and structural design and analysis. Factors that influence the tensile response and should therefore be reported include the following: material, methods of material preparation and lay-up, specimen stacking sequence, specimen preparation, specimen conditioning, environment of testing, specimen alignment and gripping, speed of testing, time at temperature, void content, and volume percent reinforcement. Properties, in the test direction, which may be obtained from this test method include ultimate tensile strength, ultimate tensile strain, tensile chord modulus of elasticity, poisson's ratio, and transition strain. For complete information on ASTM D3039 / D3039M, go to astm.org