Thermal Analysis Capabilities

Westmoreland Mechanical Testing and Research’s (WMT&R) thermal analysis capabilities strengthen the depth and quality of its testing results. Our thermal analysis can help study material changes in relation to temperature, ensuring your materials have the capability to withstand its intended application.”

Expedited Thermal Analysis Services Are Available- Contact Us Today at

724-537-3131

- Accreditations: NADCAP

- Capability for Vast Temperature Ranges from -320ºF to 3000ºF

- Ability to Analyze Material’s Properties Including Mass and/or Dimension Change, Mechanical Stiffness and Damping and/or Heat Flow as a Function of Temperature or Time

- Ability to Analyze Metals, Polymers, Composites, Thin Films, Adhesives, Ceramics and More

- Thermal Analysis For Industries Including Aerospace, Automotive, Additive Materials, Medical, Composite, Oil and Gas, and More

- Dilatometry (DIL)

- DLF - Thermal Diffusivity Instrument

- Dynamic Mechanical Analysis (DMA)

- Thermomechanical Analysis (TMA)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetry (TGA)

- Standardized Thermal Analysis Testing Solutions

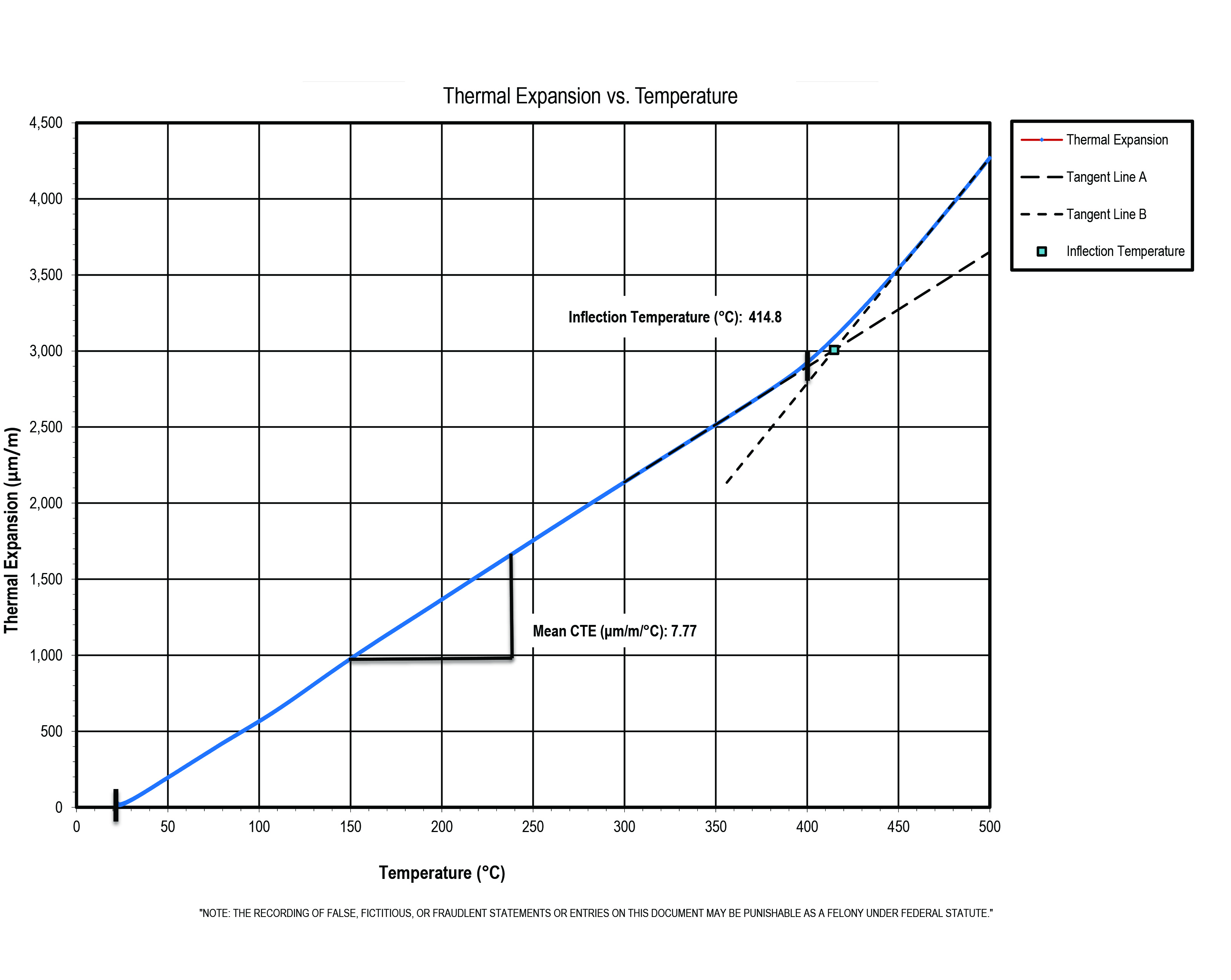

Dilatometry (DIL)

Dilatometry (DIL) is a thermoanalytical technique for the measurement of expansion or shrinkage of a material when subjected to a controlled temperature/time program. The method is standardized and operates on bases such as DIN EN 821, DIN 51045, ASTM E 831 and ASTM E 228. Besides solid samples, powders, pastes and even liquids can be tested in special containers.

- A2LA and GE accredited

The Following Graph Represents Thermal Expansion vs. Temperature

DLF - Thermal Diffusivity Instrument

What Is The Discovery Laser Flash System Used For?

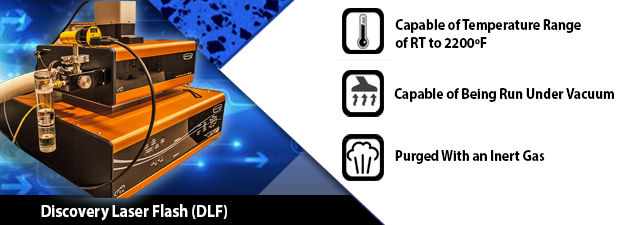

The Discovery Laser Flash System (DLF) provides Westmoreland Mechanical Testing & Research the capability of testing for thermal diffusivity and thermal conductivity.

The DLF provides a high-performance laser flash analysis over a wide range of test temperatures. With high precision, quick response, non-contact measurement of the sample surfaces, Westmoreland Mechanical Testing & Research determines your material's ability to transfer and store heat.

Discovery Laser Flash (DLF)

- Capable of a temperature range of RT to 2200ºF

- Square and circular sample geometries

- Purged with an inert gas or run under vacuum

- ASTM E1461 - standard test method for Thermal Diffusivity of solids by the flash method

- A2LA accredited

Dynamic Mechanical Analysis (DMA)

What Is Dynamic Mechanical Analysis Used For?

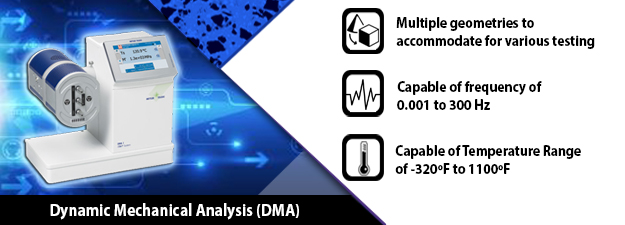

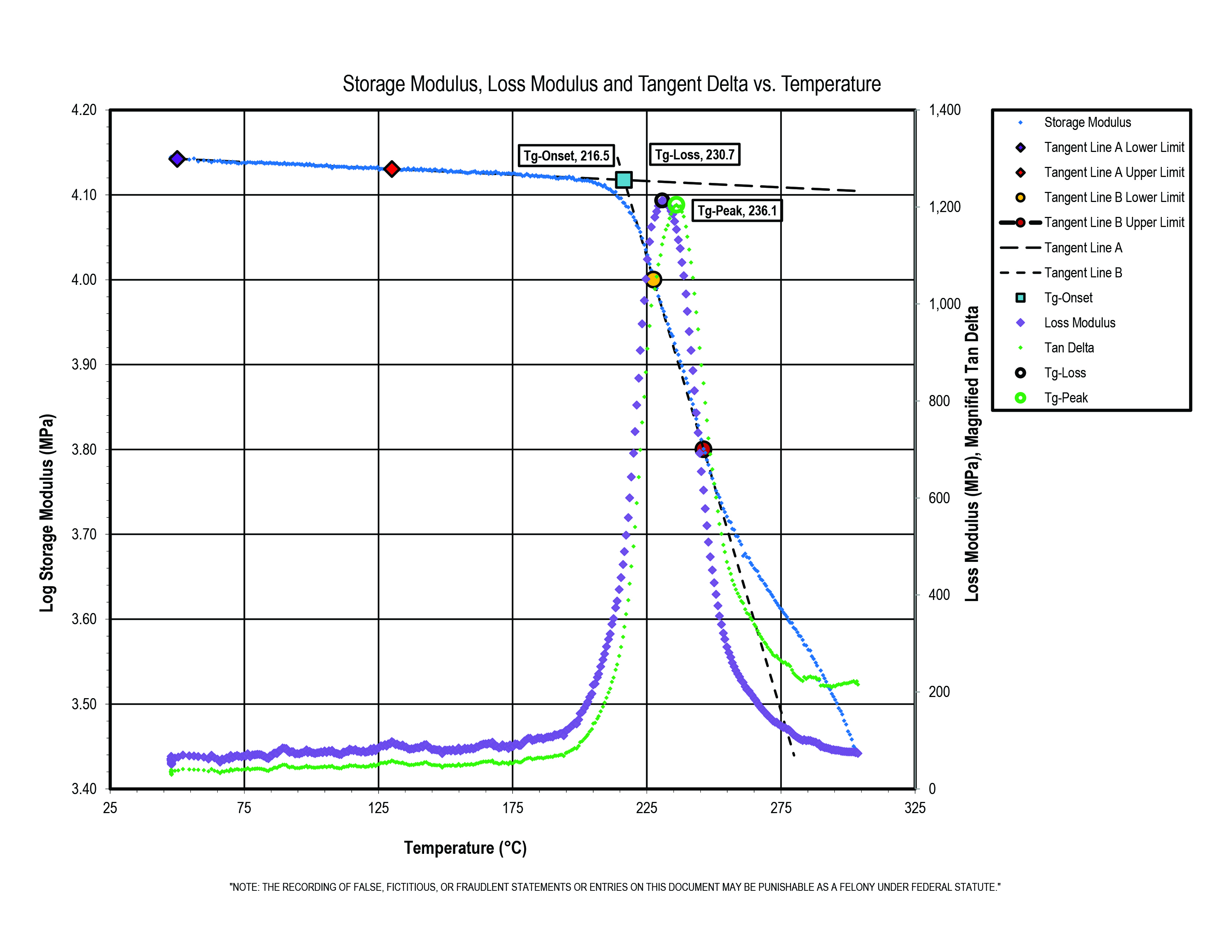

Dynamic Mechanical Analysis measures the mechanical and viscoelastic properties of materials such as thermoplastics, thermosets, and elastomers by applying an oscillatory force in a set geometry.

Customizable fixturing and furnace program for ceramic or metallic materials as well.

The DMA machine has a fluctuating temperature range as well as humidity control and fluid bath options for additional testing information for your materials.

The Following Graph Represents Plotting of Storage Modulus, Loss Modulus and Tangent Delta vs. Temperature

Dynamic Mechanical Analysis (DMA)

- Plots viscoelastic properties vs. temperature.

- Capable of temperature range of -320ºF to 1100ºF

- Multiple geometries to accommodate for various testing (tensile, compression, 3 pt. bend, single/dual cantilever, shear)

- Sample support can be inverted 180º and submerged into a fluid bath to simulate testing in various liquids (salt water, fuels, oils, etc.)

- Capable of frequency of 0.001 to 300 Hz

- Accreditations: NADCAP and A2LA

Dynamic Mechanical Analysis (DMA) Standardized Tests

- ASTM D7028

- ASTM E5023

- ASTM D5024

- ASTM D5026

- ASTM E1640

- ASTM E1867

- EN 6032

- SRM 18R

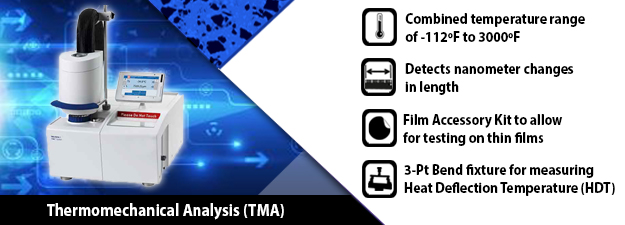

Thermomechanical Analysis (TMA)

What Is Thermomechanical Analysis Used For?

Westmoreland Mechanical Testing & Research provides Thermomechanical Analysis which studies the dimensional change of a material over a predefined temperature segment. A TMA applies a stress to a material and the resulting strain is measured while the material is subjected to a controlled temperature program.

TMA

- Combined temperature range of -112ºF to 3000ºF

- Detects nanometer changes in length

- Film Accessory Kit to allow for testing on thin films

- Multiple probe types (3mm Flat, 1mm Flat, 3mm Ball Point, Knife Edge) for optimum results and resolution

- Accreditations: NADCAP and A2LA

- ASTM E831

- ASTM E1545

- ASTM E2092

- ISO 11359

Thermomechanical Analysis (TMA) Standardized Tests

Differential Scanning Calorimetry (DSC)

What Is Differential Scanning Calorimetry Used For?

Another capability of our thermal analysis is Differential Scanning Calorimetry (DSC). The DSC measures energy changes in samples due to variations in their physical and chemical properties as a function of temperature or time.

DSC

- Capable of temperature range of -58ºF to 1292ºF

- Accreditations: NADCAP and A2LA

Differential Scanning Calorimetry (DSC) Standardized Tests

- ASTM E1269

- ASTM D3418

- ASTM E1356

- ISO 11357

- EN6041

- EN6064

- SRM 25

Thermogravimetry (TGA)

.jpg)

What Is Thermogravimetry Used For?

Thermogravimetry, through the Thermal Gravimetric Analyzer (TGA) measures the change in weight of a sample as tested through a temperature profile. The TGA can provide information about chemical phenomena including chemisorptions, desolvation and dehydration, decomposition, and solid-gas reactions such as oxidation or reduction.

- Also referred to as STA (Simultaneous Thermal Analysis)

- Measures mass and enthalpic change over a given temperature profile

- Capable of temperature range of RT to 3000ºF

- XP5 balance: Capable of samples up to 5 grams (1.0 ug resolution)

- Gas Controller to allow for inert and reactive gas atmosphere

- Accreditations: NADCAP and A2LA

Thermogravimetry (TGA) Standardized Tests

- ASTM D3850

- ASTM E1131

- ASTM E2550

- ISO 11358

Standardized Thermal Analysis Testing Solutions

Westmoreland Mechanical Testing & Research provides standardized and customized thermal analysis testing solutions, unique to your materials testing requirements.