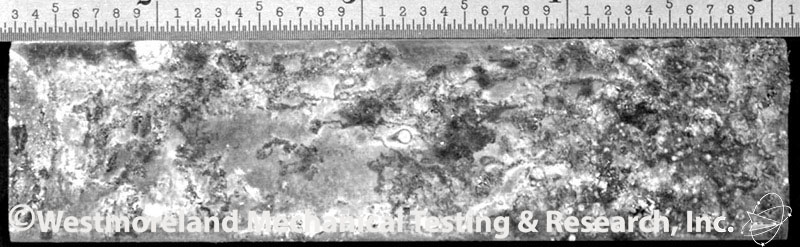

Stress Corrosion Testing

Westmoreland Mechanical Testing & Research is an acknowledged leader in Alternate Immersion Stress Corrosion Testing for the Aerospace, Automotive, and Materials industries – providing you with timely, extensive, and high-volume solutions for the material selection, processing, and treatment options related to corrosion stressors such as sweat, rain, humidity, or salt."

Expedited Corrosion Testing Services Are Available- Contact Us Today!

- Over 21+ Testing Frames

- Capacity of Testing Over 2,100+ Constant Strain Specimens

- Customizable, Uniquely Programmable Fixtures and Test Set Ups

- Flexibility and Experience to Test Large Number of Specimen Types (Including SCC, Electrical Devices, Live Load)

- Large Capacity Frames and Humidity Chambers

- What Is Corrosion Testing?

- Why Do I Need Stress Corrosion Testing?

- What Materials Should Be Tested for Corrosion?

What Is Corrosion Testing?

Corrosion testing is testing of various materials used in industrial applications to verify reliability and conformity of quality for the material.

Different corrosion tests reveal different weaknesses in material based on environmental factors which can range from temperature, physical and metallurgical situations, salt spray, and more.

Different Types of Corrosion Testing:

Immersion Testing

Immersion Testing, or, Alternate Immersion Testing is considered the most popular and simplest type of corrosion test. This versatile test is used to assess different materials that are subjected to particular conditions and can be personalized to meet specific needs regardless of application. In this test, the testing apparatus can expose the specimen to test solutions and then subject it to different physical or metallurgical situations, such as crevices and heat treatment.

Some Standardized Tests Available for Immersion Testing Include:

ASTM G31 Immersion Corrosion analysis applies to a wide range of conditions, allowing you to rapidly assess the corrosion rate of your materials and solutions.

Hot Wall Testing

Another test is the hot wall test, which is utilized to evaluate situations where metal vessels are hotter than bulk solutions. These are common in external heated vessels where corrosion is typically impacted by temperature. In this test, elevated temperatures signify high levels of corrosion activity.

Some Standardized Tests Available for Hot Wall Testing Include:

ASTM A262 Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels.

Salt Spray Testing

There is also a test known as salt spray. This technique is used to evaluate a coated sample's resistance to corrosion. This test produces an attack to coated specimens to measure suitability as a protective coating.

ASTM B117 Salt Spray (Fog) Testing

ASTM D1193

ASTM B 368 Copper-Accelerated Acetic Acid Salt Spray, (CASS) Test

ASTM G85 Standard Practice for Mo\dified Salt Spray (Fog) Testing

ASTM G85 Annex A1 Acetic Acid-Salt Spray Test, Continuous

ASTM G85 Annex A2 Cyclic Acidified salt Fog Testing

ASTM G85 Annex A3 Acidified Synthetic Sea Water (Fog) Testing

ASTM G85 Annex A4 Salt/So2 Spray (Fog) Testing

ASTM G85 Annex A5 Dilute Electrolyte Cyclic Fog/Dry Test

Additional Testing

In addition to these, there are numerous other corrosion testing techniques available that help prevent loss due to corrosion. Please contact us today to learn more about our stress corrosion testing services and how we can accommodate your next project.

Customizable Corrosion Testing Equipment

Westmoreland Mechanical Testing & Research Analytical Department has the expertise and capacity to custom design and fabricate innovative fixturing and test setups for the most difficult of customer demands including large capacity frames and a humidity chamber.

We have custom-designed, proprietary programmable frames to ensure proper time intervals between NaCl submersion and air environment exposure to ensure accurate simulation of corrosion based on your specific industry testing needs.

Westmoreland Mechanical Testing & Research has over 21 frames with the capacity of loading up to 2100 constant strain specimens ensures the agility and speed to get your job into testing without delay.

Our facility is equipped with a state-of-the-art Humidity Chamber that can be used to conduct tests as per ASTM G60.

Why Do I Need Stress Corrosion Testing?

Controlling stress corrosion cracking is an important process for materials in the design and construction stages. By choosing a material that is not susceptible to SCC in the service environment, and by processing and fabricating it correctly, stress corrosion problems can be reduced or avoided.

Stress Corrosion Testing is useful for the Aerospace, Automotive, and Materials industries to assist in material selection, processing, and treatment options related to everyday corrosion stressors such as sweat, rain, humidity, or salt. Materials that are mainly tested for stress corrosion include:

What Materials Should Be Tested for Stress Corrosion?

Many materials are susceptible to stress corrosion cracking which can lead to damage, weakness, and failure for its intended applications. Different materials are affected by stress corrosion differently, which makes testing necessary for your material testing decisions.

Performing stress corrosion testing to assist in your materials decisions will ensure it has the intended strength, durability, coating, and reliability right for its end application. We have the experience and the extensive scope to test nearly any material for any application your project requires. Some materials commonly tested for corrosion are metals, polymers, and ceramics including:

Metals

- Austentic Stainless Steels

- Aluminum Alloys

- Mild Steel

- Nitrates

- Copper Alloys

- High-Tensile Structural Steel

-

Polymers

- Polycarbonate

- Polyester

- Nylon

- Nyolon Mouldings

- Natural Rubber

- Styrene-Butadiene Rubber

- Nitrile Butadiene Rubber

- Rubber Tubing and Seals

Standardized Corrosion Testing Solutions

Westmoreland Mechanical Testing & Research has the capability and capacity to perform standardized testing solutions mimicking a variety of corrosion stressors based on your specific project requirements, including the following standardized tests:

- ASTM B117 Salt Spray Test is used to determine normal corrosion resistance to ocean water type environments.

- ASTM G85Modified Salt Spray Test is used in the Harshaw Environmental Unit to determine modified corrosion resistance to water-type environments

- ASTM B368Copper-Accelerated Salt Spray Test is used to evaluate the corrosive performance of decorative copper/nickel/chromium or nickel/chromium coatings on steel, zinc alloys, aluminum alloys, and plastics designed for severe service.

- ASTM B368 CASS Test) is widely used to evaluate aggravated conditions such as road salt on automotive parts.

- ASTM G48 Pitting and Crevice Corrosion Test is used to determine the resistance of stainless steel and related alloys to pitting and crevice corrosion when exposed to oxidizing chloride environments.

- ASTM G67 Crevice Corrosion Test (NAMLT Test) is used to provide a quantitative measure of the susceptibility to intergranular corrosion of Al-Mg and Al-Mg-Mn alloys.

- ASTM G34 Corrosive Exfoliation is used to provide research and development purposes as well as specific material specifications applicable for evaluating production material and prediction of exfoliation corrosion behavior.

- G66 ASSET Test

- ASTM G28 Intergranular Corrosion Test is used to determine the susceptibility to intergranular corrosion in wrought, nickel-rich, and chromium bearing alloys.

- ASTM A262 Intergranular Corrosion Test is used to determine the susceptibility to intergranular corrosion in wrought, nickel rich, chromium bearing, and stainless steels.

Some of our other Corrosion Testing Services includes:

- Exfoliation

- C-Ring

- Round and Flat Tensile

- Bent Beam

- Alternate Immersion

- SCC Testing of High Strength Aluminum Alloys

- SCC Testing in accordance with ASTM G38, G44, G47, G49

- Direct Tension

- Asset

- U-Bend

- Constant Load Capabilities

For a Complete List of Corrosion Testing Services, Please Request A Quote or Call 724-537-3131.